≡ Catalogar

|

|

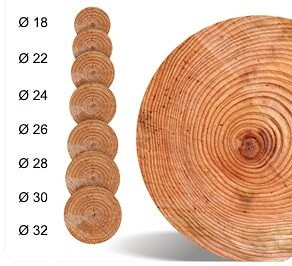

Wooden houses production technology Production of wooden houses must comply with the approved technology for the production of prefabricated wooden structures to achieve the best results. Stage, known as "the production of wooden log houses," or houses made of wood, lasts only two or three weeks, and it can be divided into several parts. Production of wooden houses must comply with the approved technology for the production of prefabricated wooden structures to achieve the best results. Stage, known as "the production of wooden log houses," or houses made of wood, lasts only two or three weeks, and it can be divided into several parts. The first one - selection of high quality material - wood, from which the logs, or profiled timber wooden structures are build . The material for the production of wooden houses, baths, or even restaurants and hotels from the wood, we bought on the spot - in the Vitebsk region - an environmentally clean and free of radionuclides region of the country - or comes from Russia - the North, Krasnoyarsk Territory. As a rule, we have available the necessary amount of material for the production of wooden structures, and the customer does not wait for round logs or laminated veneer lumber will be ready for processing. The second part - just the production of parts of wooden houses. The company "ArchiLine" has its own production, which involves highly skilled staff and modern equipment. Production of wooden houses of timber and logs is a complex and interesting process. At its heart - modern technologies of wood processing, reliable equipment and skilled personnel. ArchiLine production of wooden houses based in Vitebsk region of Belarus which is ecologically clean, free of radionuclides region of Belarus. Wood for manufacture of wooden houses is bought locally or imported from Russia - the North, Krasnoyarsk region. In the production of lumber and logs the following machines are involved: Cuting machine that provides the perfect straightness and accuracy of the diameter of the logs. Special marking line, which eliminates the error in interaxle size with a tolerance of 0.5 mm, excluding human error, eliminating thus air flow through the wooden house that arises from the disruption of project sizes in the manufacturing process. Anglecut machine that allows to make bay, dock walls at any angle, even on large diameter logs. A special milling machine, able to read part of the longitudinal inner surface of the timber for a flat wall in a wooden house. Using the previously agreed with the Customer detailed design of a wooden house from profiled timber or rounded logs, our experts produce the basic components and related wooden frame using a unique wood-processing equipment of world famous brands. The third part of the production phases - wood protection. We are focused on protecting the wood from rotting. We use a special antiseptic quality, instead of the usual traffic. We use the method of dipping timber in a bath, which eliminates the further emergence of a fungus and mold on the wooden frame. The final part of the production process of wooden houses - packing and shipping of ready-to-install kits. Kit to build a house made of wood wrapped in a special way, thus reducing overall construction time of wooden houses at the expense of a minimum time of discharge kit. We speak english, russian and german:+375298-06-05-67 — WhatsApp, Viber, TelegramMira más:Puedes ver una reseña en video de la casa de madera "Casa Blanca" de madera laminada encolada Archiline Houses: Puede ver una revisión en video de la casa de madera "Mirage": Si desea comprar wooden houses production technology , puede:

Más de la sección Ahşap malzemeler |

|

© 2024

ArchiLine Wooden Houses

114-49, Necrasov str., Minsk, Republic of Belarus, 220049

El sitio funciona con Nestorclub.com | |

Good Wooden House since 2004

Good Wooden House since 2004